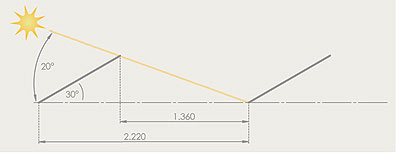

There may be a problem with the current Silver Spray plans and the angles for the solar panels. The current plan is for the panels to be bolted onto the proposed flat roof at the back.

- Solar panels should be south facing and between 20 and 60 degrees.

- I’ve heard / read that the ideal angle for solar panels in Cornwall is for them to be at 30 degrees (and south facing).

- Below 20 degrees panels don’t self-clean when it rains. Dirty panels are less efficient

- The angle that solar panels are normally mounted on flat roofs is usually low to reduce the amout they can get grabbed by the wind and ripped off the roof !

- It could just be that a framework for the panels is factored into the building so that there is no chance it can be ripped off by the wind.

- Flat roof mounting systems for panels all seem to be at about 10 degrees, so that the gap between panels is around 38 cm, and so that their is reduced possible “wind load”

- Current rear flat roof area is about 4.1 x 8m = approx 32.8 sq m. If panels are all flat, a 4kW system takes about 28 sq m. So will need to see how the space works out.

- See http://www.bauder.co.uk/photovoltaics-and-rooflights/photovoltaic-energy/baudersolar/pv-modules – images below – gap between panels moves up to 1.36m from 0.38m as solar panel angle of tilt changes from 10 to 30 degrees. But see reasons below for wanting 20 degrees or more tilt.

- The Energy Saving Trust matrix for PV angle of tilt and how much south facing, that suggests optimum is south facing and between 20 and 30 degrees tilt.

- More vertical panels do better in the winter, when the sun is lower in the sky. You are more likley to want more hot water in the winter (for space heating) and more electricity generation (to power feed the air source heat pump). BUT only 10% of generation output will be in the winter, so best to angle the panels for max, over the year, output.

I ran figures through the Energy Saving Trust calculator for a few variations at the Silver Spray postcode location:

- South slope, XLarge 4Kw, 90 degrees = 2,688 kWh pa

- South slope, XLarge 4Kw, 60 degrees = 3,499 kWh pa

- South slope, XLarge 4Kw, 50 degrees = 3,643 kWh pa

- South slope, XLarge 4Kw, 40 degrees = 3,716 kWh pa

- South slope, XLarge 4Kw, 30 degrees = 3,715 kWh pa

- South slope, XLarge 4Kw, 20 degrees = 3,640 kWh pa

- South slope, XLarge 4Kw, 10 degrees = 3,492 kWh pa

- South slope, XLarge 4Kw, 0 degrees = 3,274 kWh pa