A great report by the School of Engineering at Napier University in Edinburgh on windows:

Frames of different materials have been assessed on the basis of their production, energy consumption and environmental impacts.

The investigation shows that aluminium and PVC frames exhibit large amounts of

environmental burdens. Accelerated ageing tests have been carried out to test the

durability of windows against weathering impacts. These tests show that aluminium clad timber windows are comparatively least affected by environmental impacts.

CONCLUSIONS (from the article)

- Aluminium frames cause the highest burden to the environment because of the dangerous pollutants release and high energy consumption during aluminium production. PVC contributes large amounts of poisonous pollutants throughout its life cycle, while timber window frames have the least environmental burdens.

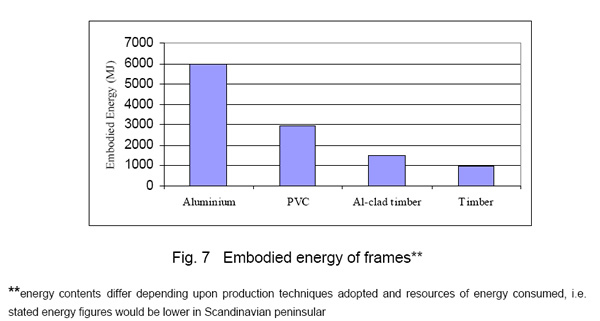

- Embodied energy analysis has been carried out for a standard 1.2m × 1.2m window. Aluminium windows have the highest embodied energy, amounting to 6GJ. PVC, Al-clad timber and timber windows have embodied energy of 2980MJ, 1460MJ and 995MJ respectively.

- All frame materials deteriorate to various degrees by environmental impacts. PVC is sensitive towards heat and UV radiation. Timber if not frequently treated, can easily be affected by environment. Aluminium, if not protected well by coatings, gets damaged under corrosive conditions especially in coastal and industrial areas. Al-clad frames are unlikely to deteriorate due to their protective coatings and appear to be the best choice from this point of view.

- A survey analysis shows that aluminium and timber windows can easily last more than 40 years. Al-clad timber being new on the market, is expected to have a service life well over 40 years. PVC windows, in most cases, are reported to have an optimum service life of 25 years.