A lot going on, with the build and with other things, so a long while since an update.

The relentless UK weather of high rainfall and strong winds that have flooded large sections of the UK and battered the Cornish coastline has slowed down the daily work rate and meant that some items, such as the dry roof membrane for the flat roof, is not yet done.

The stormy sea from the house:

The roof had a mesh of timbers put on, with marine ply over the top, to give a gentle slope from a central ridge for the “flat” roof:

You can see the level drop in this photo:

At the same time, the internal studwork is going up:

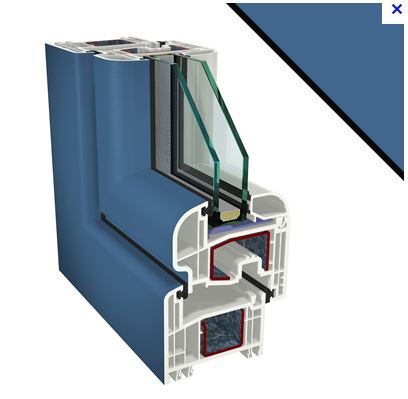

The window frames are going in (the white tape comes off later !):

and a bit more of the garage has been built:

Despite looking bigger than it will due to the scaffolding and lack of cladding and other details that will soften the impact of the size, it’s shape is now there: