I’m going to have a problem, sorry challenge.

The sliding doors from the planned living room at the bottom are due to be around 2.8m tall.

This is taller than most companies produce triple glazing. In part due to the total weight of the glazing units.

Triple glazing gives better insulation, and less thermal gain. But as this is north facing, the solar gain isn’t an issue.

- The very best double glazed windows are already capable of being net heat contributors over the course of a heating season. In contrast, triple glazed windows slightly reduce the heat absorption characteristics of a window.

BUT, how much more expensive is triple glazing and how much better is it ?

- http://www.homebuilding.co.uk/advice/key-choices/green/triple-glazing

- Current Building Regulations insist that any window you install today should have a U-value no worse than 1.6.

– for reference, walls should be less than 0.3. So windows are a thermal weak spot. - PassivHaus standard requires triple glazed windows with a Uvalue of no more than 0.8.

- Although a U-value as low as 0.8 sounds very impressive, the additional energy we are saving is minuscule whilst the payback time for triple glazing (like double glazing) is high compared to other energy-efficiency improvements. So why bother ?

The key benefits are really to do with comfort. If you insulate the walls, roof and floor of a house, and you ignore the glazing, you end up with cold spots surrounding the windows at night, which cause draughts, draw heat away from you if you sit next to them, and can result in streams of condensation running down the panes. So, in essence, the standard of glazing has to match the standard of the insulation elsewhere in the house, so that the warm wrapping around the house performs consistently.

The PassivHaus Institute, in Germany, has looked at the surface temperatures on various forms of glazing when it gets really cold outside, and the internal air temperature is designed to be at 21°C:

- Next to a single-glazed window, the internal surface temperature is around 1°C.

- Next to a double-glazed window (2000 vintage), the surface temperature is around 11°C.

- Next to a modern, energy-efficient double-glazed window, the surface temperature is 16°C.

- Next to a triple-glazed window, with a centre-pane U-value of just 0.65, the temperature is 18°C.

So whilst triple glazing may make little difference to your heating bills, you will notice the difference inside the house.

BUT, this is all based on the situation in Germany, where it’s a lot colder than the UK. Cornwall is itself a relatively warm bit of the UK.

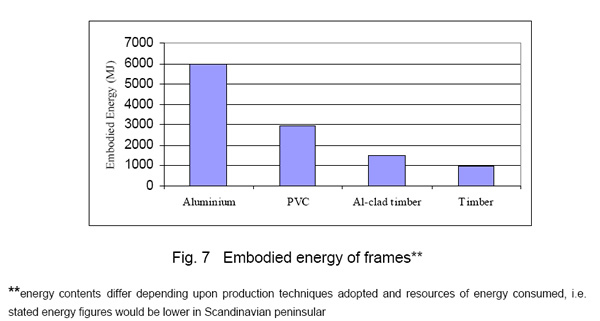

The upshot of this is that there are many who argue that triple glazing simply doesn’t make sense in a climate like ours. Triple glazing is more costly to produce, produces much heavier sections and has an embodied energy approximately 50% higher than double glazing.

An alternative option that might make more sense is to revisit the traditional practice of drawing curtains across windows after dark. It may be low-tech, in comparison with glazed cavities filled with krypton, but it’s something of a natural British habit and it does cut down on heat loss. Perhaps it’s time we paid attention to improving the heat retention characteristics of curtains and blinds, rather than continuing to engineer glazing units to ever lower and lower U-values.

- Maybe, as a life style strategy, I’ll have curtains, that I might only draw when I go to bed, or some time after it gets dark. But curtains and top efficiency double glazing could be the way to go.