I’ve come across the GreenServeUK website with new info on the Thermodynamic Panels.

There’s a big FAQ at http://www.greenserveuk.com/faq/

How it works from http://www.greenserveuk.com/thermodynamics/how-they-work/

Step One

The environmentally friendly refrigerant liquid is fed into the veins of the solar collector.

This refrigerant (R134A) has a boiling temperature of -25°C. The panel absorbs the heat from the environment and raises the temperature of the refrigerant.

The liquid absorbs the heat and it vaporises into a gas which increases the pressure.

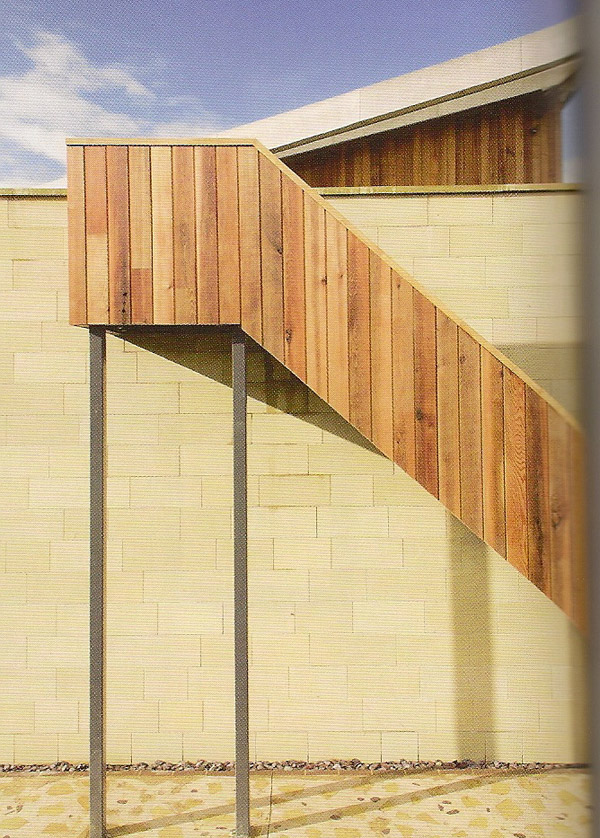

Thermodynamic Panel Dimensions are h 800mm, l 2000mm, D 20m.

Each panel is about 8 kg.

Step Two

The hot gas is then passed through a compressor where the pressure causes it to heat further.

Step Three

The heated gas is then passed into the heat exchanger where the heat is transferred into the water cylinder.

Step Four

The cooling gas then passes through a valve reverting back into a liquid where it runs back into the panel where the process begins again.

The system is a solar domestic hot water system in which the solar loop operates on a similar principle of a heat pump.

It is composed of:-

- An unglazed heat absorber (1) with 3.20 m2 total aperture area.

- An insulated, hot water thermal store (200 l) (2)

- A thermoblock, which comprises the electrical powered compressor (5), the thermostatic expansion valve (7), the electrical heating element (4) and the controller.

- Heat transfer fluid (refrigerant R134a)

The heat transfer fluid in the solar loop is the refrigerant R134a.

The refrigerant is passing through the absorber and evaporates while collecting energy from the surroundings.

The evaporated refrigerant is sucked by the compressor which raises the pressure.

In the condenser, which is integrated as an immersed solar-loop heat exchanger in the lower part of the store, the refrigerant condenses while transferring its condensing heat to the domestic water in the store.

Before the refrigerant is returning to the absorber, a thermostatic expansion valve is reducing the pressure.

An electrical heating element is located in the lower part of the store at the height of the solar-loop heat for use in emergencies and for the anti-legionnaires system.

The magnesium anode (8) or sacrificial anode will extend the life of the tank.